Contamination Control Strategy Evidence — Not Just Counts

From particle limits to source attribution across the full sterile lifecycle (EU Annex 1 and US GMP expectations).

We Give You the Data to Control

EU Annex 1 and US sterile manufacturing expectations increasingly require a living Contamination Control Strategy (CCS) | continuous, risk-based, and backed by evidence that explains what is happening and why.

SizeID.bio provides that evidence. We analyze large particle populations and microbial structures across your process using deep-learning imaging for targeting and Raman-based identification with integrated spectral algorithms for discrimination. So QA and manufacturing teams can link excursions to sources, mechanisms, and CAPA.

CCS Begins With Understanding the Whole Lifecycle

-

Identify foreign matter and recurring patterns early—before they enter production. Support supplier qualification, incoming inspection, and risk-based controls.

-

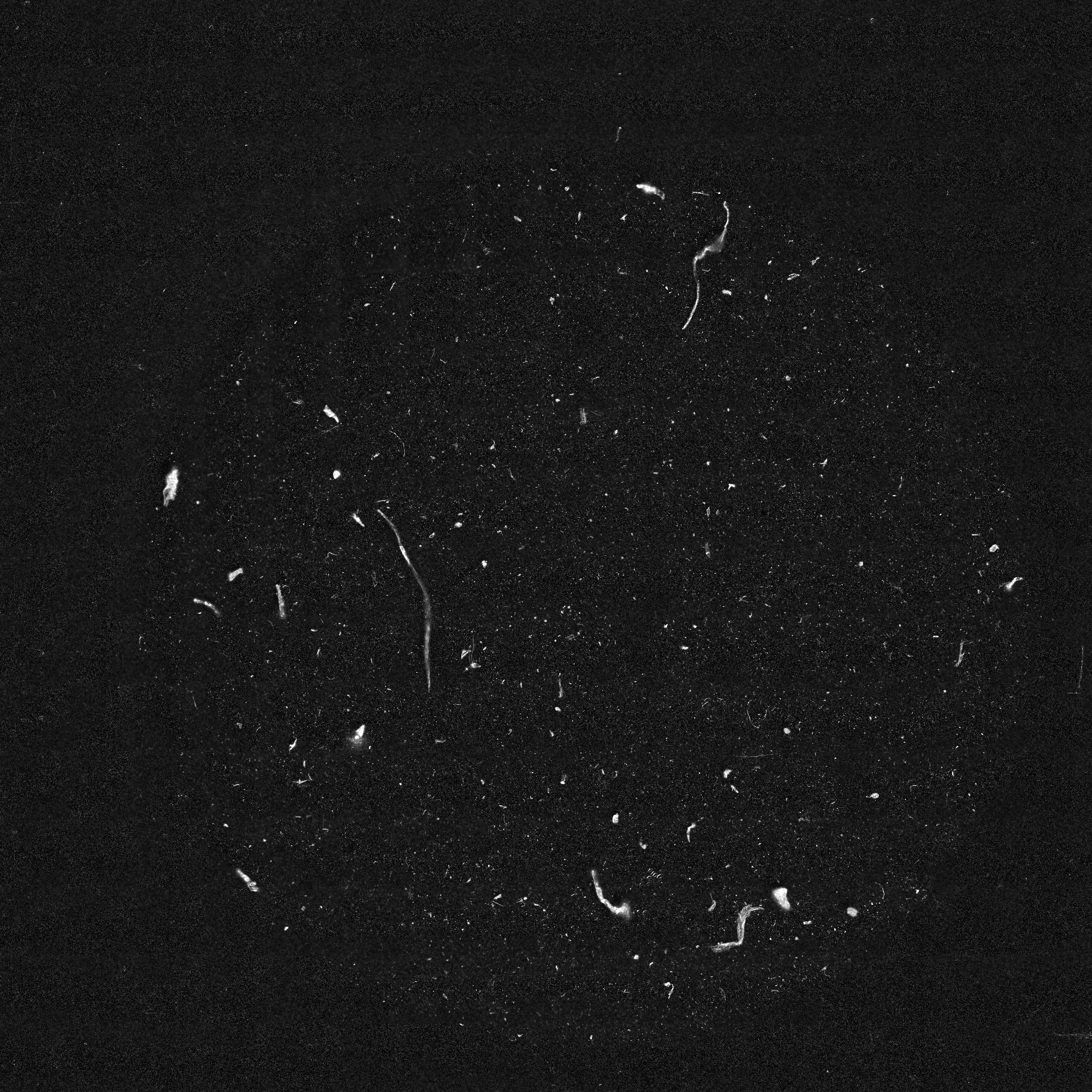

Monitor microbes and particulates together. Reveal biofilm-related shifts, corrosion signatures, polymer residues, and other contributors that simple counts can miss.

-

Explain excursions across cleanroom zones by differentiating typical contributors (skin, fibers, equipment wear, packaging residues) and highlighting emerging patterns.

-

Detect drift, equipment wear, cleaning issues, and process-related shifts through particle population changes and material attribution.

-

Quantify contributions from silicone, rubber, polymers, glass, and steel—supporting component risk assessments and investigation narratives.

-

Contextualize reject trends and long-term changes by tying "what is seen" to "what it is," enabling targeted remediation and comparability arguments.

Tyvek (Stopper Bag)

Cellulose

Polystyrene